مؤسسة أفنان الشروق للمقاولات العامة

AFNAN AL SKOROUK FOR GENERAL CONTRACTING EST.

NOURA AL NIZI EST. Precast manufacturing facility located in Riyadh, Providing a wide range of precast concrete products for sanitary sewer system, storm drainage, and custom structures, with delivery service to all of the KSA areas and the Gulf countries. We are following the specification of ASTM (American standards test measurement) for all of the concrete products.

Astm Standard:

C478: standard Specification for Circular precast Reinforced concrete Manhole Sections.

C67: standard Specification for Reinforced concrete Culvert Storm Drain, and Sewer Pipe.

C139: standard Specification for Concrete Masonry Unite for Construction of Catch Basin and Manholes.

C497: standard test Methods for concrete pipe, Manhole Sections, or Tile.

A615: standard Specification for Deformed and plain Carbon-Steel Bars for concrete reinforcement.

C33: Standard specifications for Concrete Aggregates.

C94: Standard specifications for Ready-mixed Concrete.

C150: Standard specifications for Portland cement.

C949: Standard specifications for chemical Admixtures for Concrete.

C685: Standard specifications for Concrete Made by Volumetric Batching and Continues Mixing.

C39: Standard specifications for Method for Compressive Strength of Cylindrical Concrete Specimens.

C443: Standard Specification for joints for concrete pipe and Manholes, Using Rubber Gaskets.

Manufacturing Process:

Following are the stages in manufacturing Process sing wet cast spinning method or vertical semi dry cast method1

Forming Steel Reinforcement Cages.

Concrete Mixing and feeding.

HDPE Lining or any suitable required lining.

Casting Pipe and Manhole.

Demolding and Curing.

Coating & Marking.

Our products:

Sanitary Sewer System Manholes.

Storm Drainage Manholes.

Catch Basin.

Lighting Pole Basis.

Concrete Barriers.

Electric and Communication Chambers.

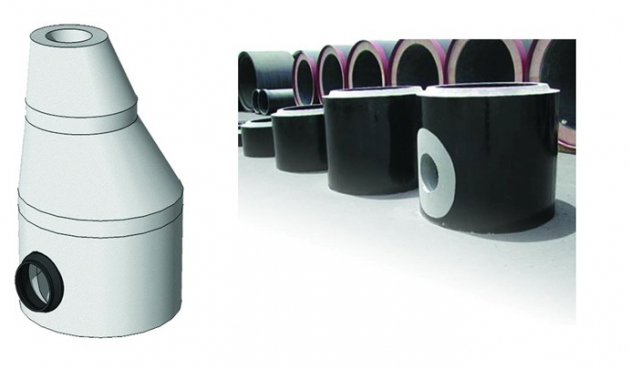

Circular Manhole:

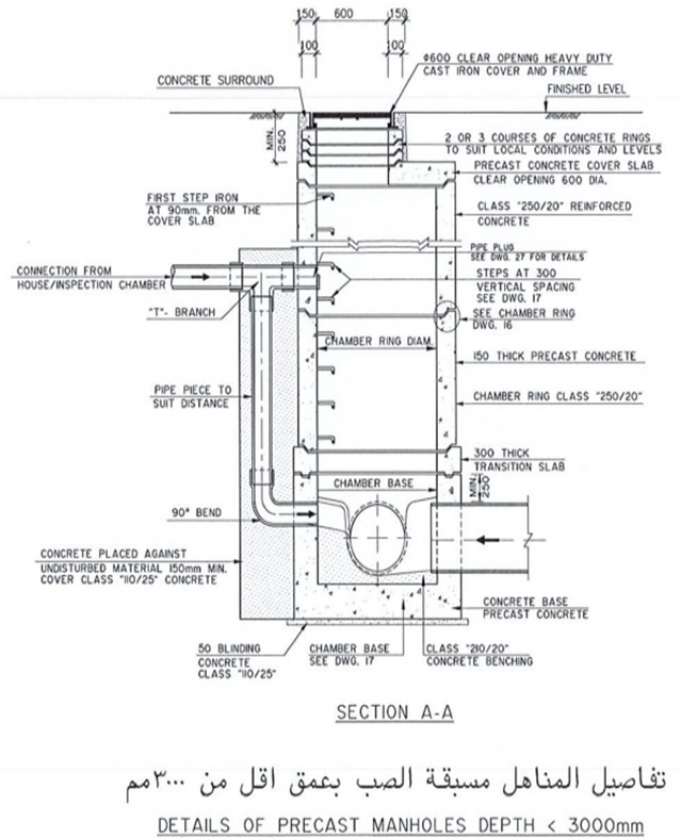

Circular manhole is manufactured for the sanitary sewer system and storm drainage, according to ASTM C 487. Manholes Are Manufactured In Diameters from 600 mm to 2500 mm. The Manhole depth can be adjusted using various manhole elements (risers and adjustment rings) according to the site requirements.

Manhole Consists Of the Following Sections

-Base Ring

-Riser Rings in Standard Variable Heights of 300, 600, 900, 1200 and 1500 [mm]

-Grade Slab with Opening or Eccentric Cone.

Lining of manhole

Based on the customer requirement some precast circular manholes especially for sewerage system lined with (PVC, HDPE & GRP) to prevent chemical attack from the sewerage water and to prevent damages arising out of such contamination and chemical reaction.

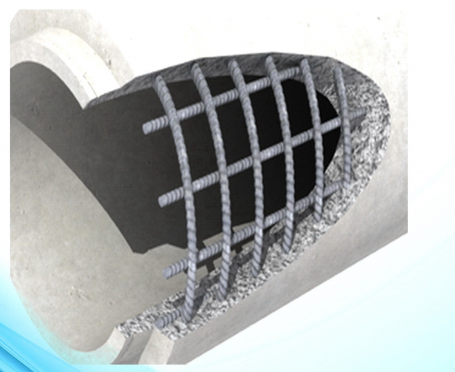

Reinforcement of the manhole

The reinforcement of the manhole is based on the customer requirements. The specification of the reinforcement is usually approved by the owner of the project who is the National water company for the sanitary sewer system, and the Ministry of Municipal and Rural Affairs for storm drainage manhole.

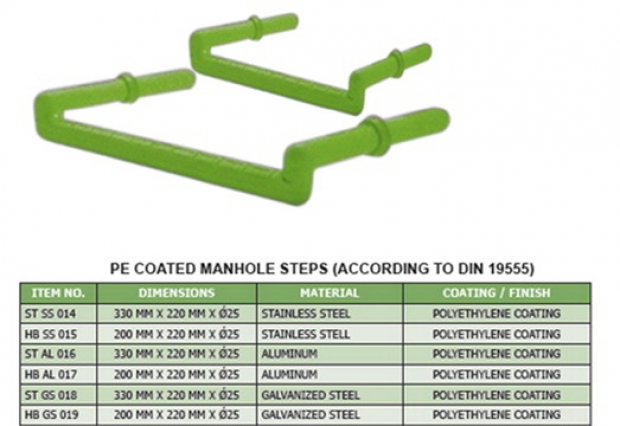

Manhole Steps :

The steps of the manhole are installed as the customer requirements

Manhole steps are designed for direct installation, using of plugs or additional installation into concrete parts (if not specified in description). Steps are produced in three versions of Galvanized Steel, Stainless Steel, and Aluminum.

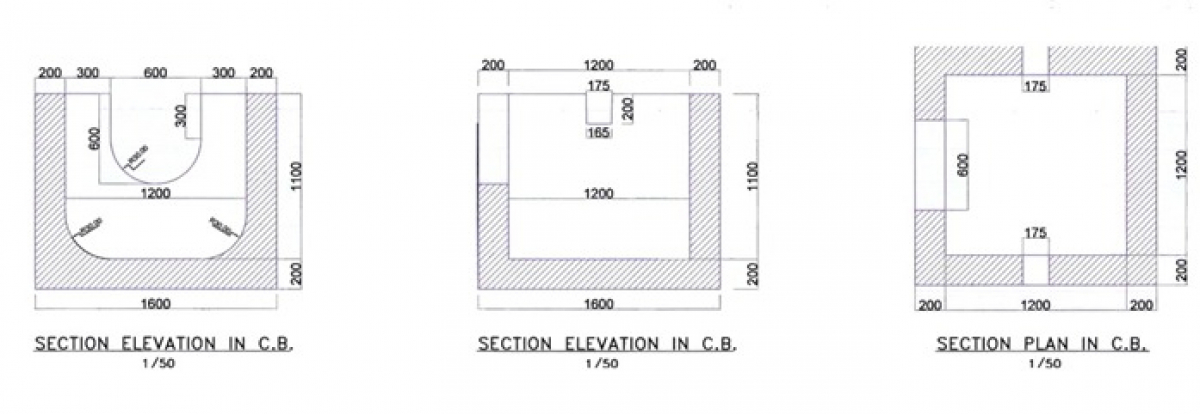

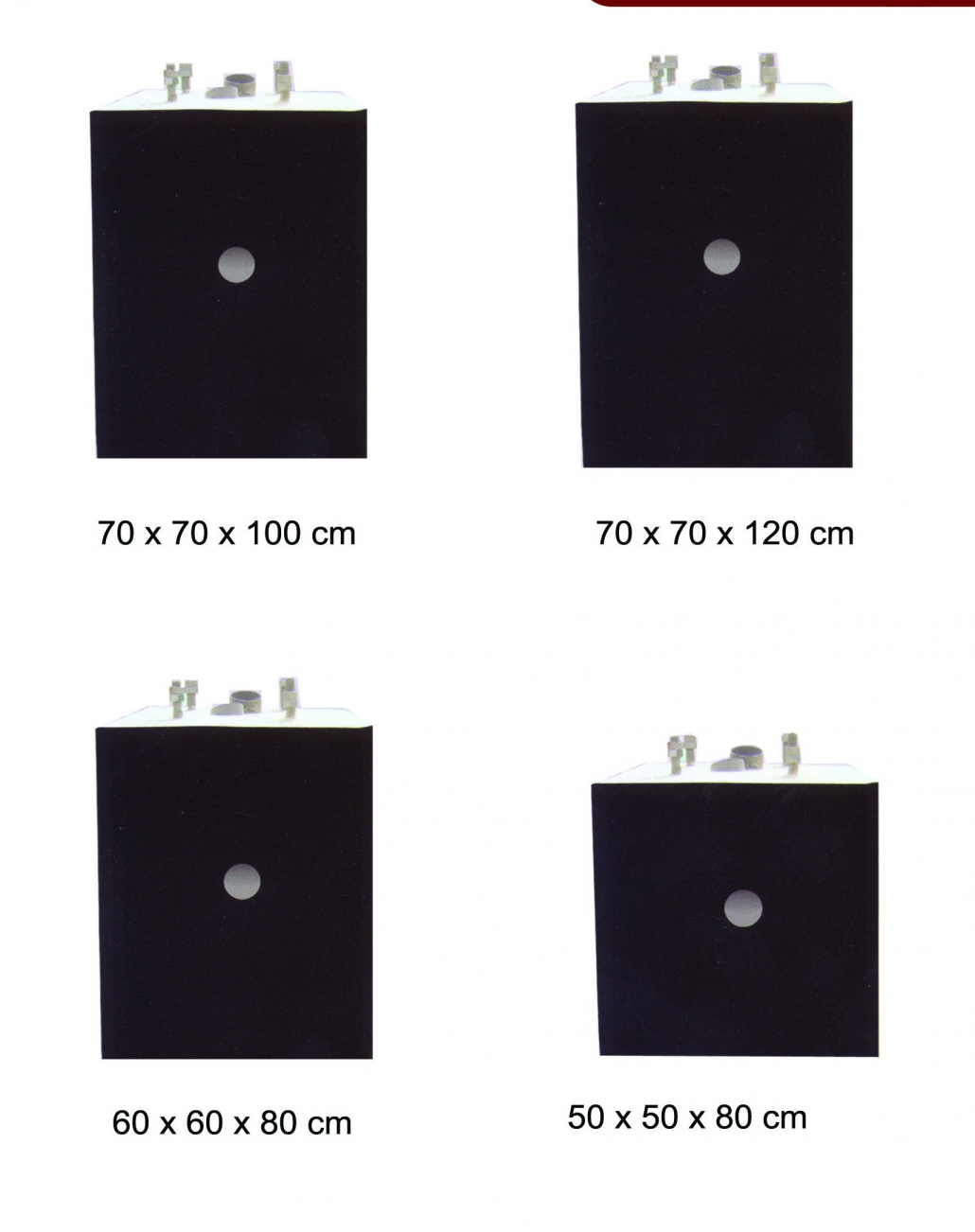

Catch basin:

Catch basin Is used in storm drainage system for collecting debris carried by effluent and their subsequent removal.

our concrete factory produce Catch basin, in different sizes as the customer requirements.

Lighting Pole Basis:

our concrete factory produce light pole bases in its modern production facility with complete control of concrete supply, FORMS and production methodology which ensures a high quality, consistent product.

Designed to meet municipal and highways specifications

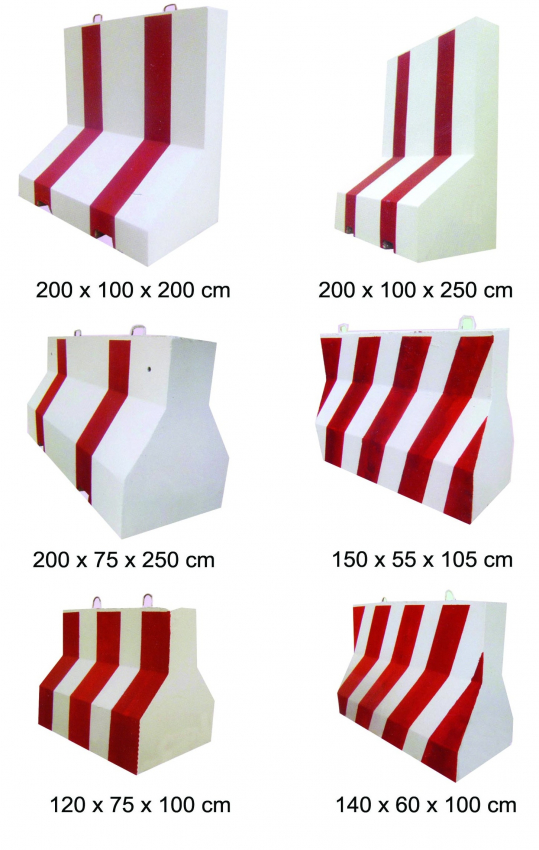

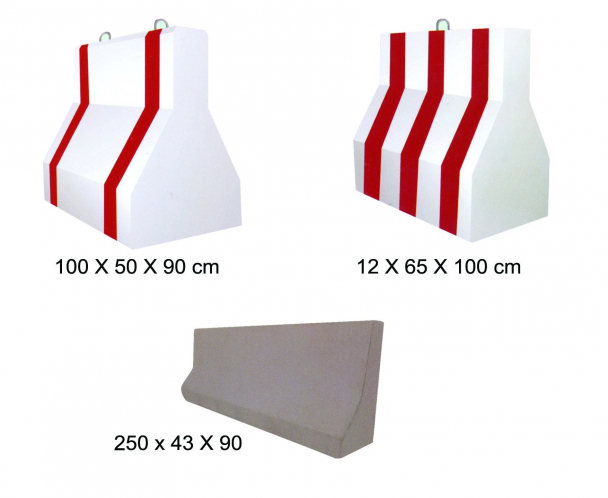

Concrete Barriers:

our factory produce Concrete barrier in its modern production facility with complete control of concrete supply, FORMS and production methodology which ensures a high quality, consistent product.

Designed to meet municipal and highways specifications

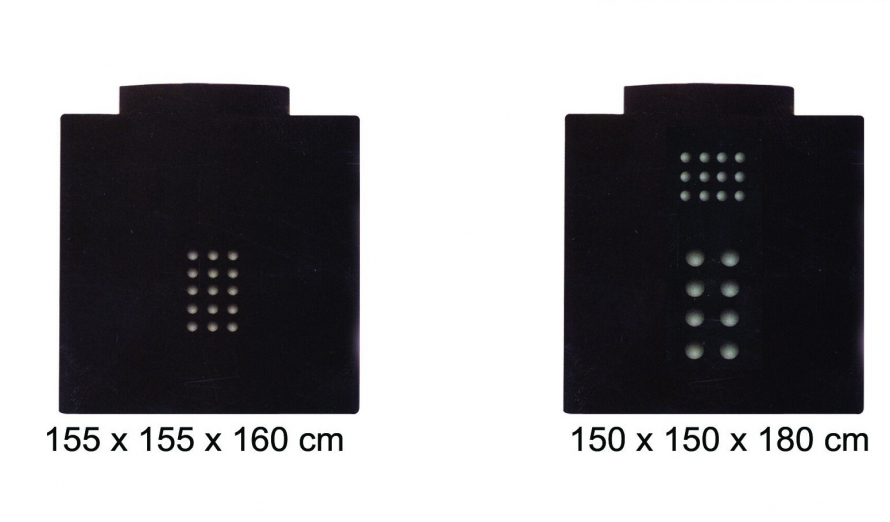

Electric and Communication Chambers.

The intent of a manhole is to provide housing in which to install splices or assist in Cable pulling operations when duct runs exceed the reel length of a certain cable, or the duct run exceeds the allowed number of bends. Manholes can also be used to break into and extend from existing conduit systems to maintain the connectivity of the system.

we produce Electric and Communication Chambers in its modern production facility with complete control of concrete supply, FORMS and production methodology which ensures a high quality and consistent product.

Quality Control

To ensure the customer's requirements, we implement quality control procedures.

Every step in the process of the concrete manufacturing, from the

quotation to transport the final product to the customer

should be checked or tested. The results should be

documented. The quality control procedures that we implement

are part of ISO 9001:2008 procedures.

The Quality control procedures are the following:

Ensuring that the Quotation is sent in correct form.

Ensure that the specification and drawing that received from the

customer are clear.

Ensuring that the raw materials are as the specifications.

Checking that the size and shape of the reinforcement are as the specification.

Checking that the form is clean before using it.

Checking the size of the forms every 3 months.

Ensuring that the lining is made as the customer requirements.

Doing strength test on the concrete using the lap.

Doing the leakage test.

Checking that the curing is made in correct method.

Checking that the coating is made as the customer requirement.

Checking that the marking is made in correct method.

Issuing non conformity case in term of non- conformity products.

Ensuring that the products that show nonconformity are stored in non-conformity storage area

Ensuring that the final product is transported to the customer as the specification in term of quality and quantity.